Self Drilling Anchor System Accessories

What Are Self Drilling Anchor System Accessories?

Self drilling anchor accessories are auxiliary components used together with hollow anchor bars to complete the anchoring process.

They enable drilling, load transfer, rod connection, and corrosion protection during and after installation.

A complete accessory system ensures:

Proper load distribution

Secure rod connections

Efficient drilling and grouting

Long service life in harsh environments

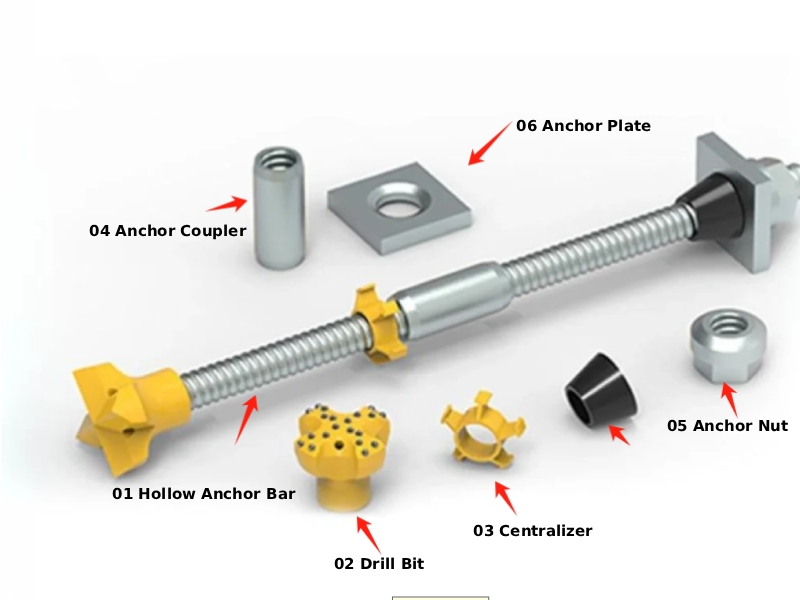

SDA System Components

- 01 Hollow Anchor Rod: Threaded hollow steel rod used for drilling, grouting, and permanent anchoring with high tensile .

- 02 Drill Bit: Sacrificial drill bit for efficient penetration, available in cross, button, or clay types matched to anchor size.

- 03 Centralizer: Steel plate distributing anchor load evenly to the supported structure or ground surface.

- 04 Coupler: Threaded steel coupler connecting anchor rods to achieve greater drilling depth and continuous load transfer.

- 05 Anchor Nut: Heavy-duty threaded nut securing the anchor system after installation and ensuring reliable load transmission.

- 06 Anchor Plate: Cement-based grout injected through the hollow core to bond surrounding ground and provide corrosion protection.

Self Drilling Anchor Types & Specifications

| R Thread Type | Outer Diameter | Inner Diameter | Steel Grade | Yield Strength | Typical Applications |

|---|---|---|---|---|---|

| R25 | 25 mm | Customized | Alloy Steel | ≥ 500 MPa | Slope stabilization, light tunneling |

| R32 | 32 mm | Customized | Alloy Steel | ≥ 500 MPa | Tunnel support, foundation works |

| R38 | 38 mm | Customized | Alloy Steel | ≥ 500 MPa | Mining, rock reinforcement |

| R51 | 51 mm | Customized | Alloy Steel | ≥ 500 MPa | Heavy-duty anchoring, deep foundations |

Custom R Thread Self Drilling Anchor

OEM R Thread Self Drilling Anchor

Sdarockbolt support comprehensive customization services:

Anchor length and diameter

Thread type and pitch

Surface treatment and corrosion protection

Packaging and labeling

Project-specific technical requirements

Our engineering team works closely with customers to deliver optimized anchoring solutions.

Material & Corrosion Protection Options

To meet different environmental and project requirements, we offer multiple material and surface treatment options:

Base Material: High-strength alloy steel

Surface Finishes:Black / Plain, Hot-dip Galvanized, Epoxy Coated

Corrosion Resistance Levels:

Suitable for temporary or permanent ground support applications.

R Thread Self Drilling Anchor Applications

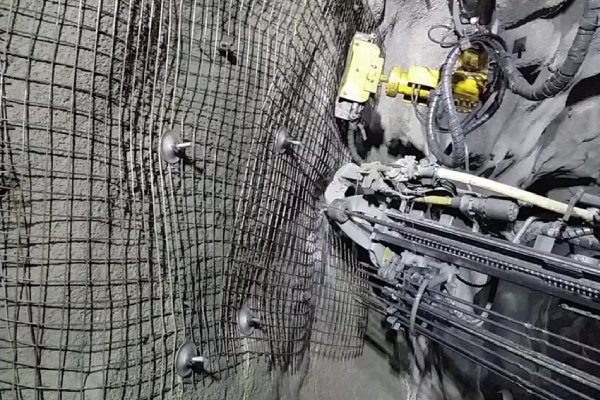

Self drilling hollow grout anchors are widely used in: Tunnel and underground excavation support, Slope stabilization and landslide prevention, Mining and rock reinforcement, Foundation and underpinning works,Rock bolting in difficult geological conditions

Soil Nailing

Tunnel and Metro Support

Slope Stabilization in Highways

Buildings Foundation Reinforcement

Underground Mining Support

Self Drilling Anchors vs Traditional Anchoring Methods

| Comparison Item | Self Drilling Anchor | Traditional Anchor |

|---|---|---|

| Borehole Stability | Excellent | Poor in loose ground |

| Installation Speed | Fast | Slow |

| Ground Adaptability | High | Limited |

| Construction Safety | High | Lower |

| Overall Cost | Optimized | Higher in difficult ground |