Grouting Pipe Manufacturer

What's Grouting Pipe ?

A grouting pipe is a steel pipe used to inject cement-based or chemical grout into soil or rock formations.

It plays a critical role in improving ground stability, sealing voids, and transferring loads in geotechnical applications.

Grouting pipes are commonly used for:

Soil reinforcement

Water sealing

Ground improvement

Key benefits of Our Grouting Pipes:

- High tensile steel materials

- Precision-controlled inner and outer diameters

- Excellent pressure resistance

- Smooth internal surface for stable grout flow

Grouting Pipe Specifications

| Outer Diameter (mm) | Inner Diameter (mm) | Wall Thickness (mm) | Standard Length (m) | Thread Type (Optional) | Pipe Type |

|---|---|---|---|---|---|

| 25 | 18 | 3.5 | 1.0 / 2.0 / 3.0 | None / External | Standard |

| 32 | 24 | 4.0 | 1.0 / 2.0 / 3.0 | External | Threaded |

| 38 | 28 | 5.0 | 1.5 / 2.0 / 3.0 | External | Threaded |

| 42 | 32 | 5.0 | 2.0 / 3.0 / 4.0 | External | Perforated |

| 48 | 36 | 6.0 | 2.0 / 3.0 / 4.0 | External | Standard |

| 51 | 38 | 6.5 | 2.0 / 3.0 / 4.0 | External | Perforated |

| 63 | 50 | 6.5 | 3.0 / 4.0 / 6.0 | External | Heavy Duty |

Custom Grouting Pipe Options

OEM Grouting Pipe

Sdarockbolt support comprehensive customization services:

-

Pipe length up to 6 meters

-

Customized hole diameter and spacing

-

Threaded or non-threaded ends

-

Surface treatments for corrosion resistance

-

OEM branding and project marking

Our engineering team works closely with customers to deliver optimized anchoring solutions.

Why Choose SDAROCKBOLT as Your Grouting Pipe Manufacturer?

As a grouting pipe manufacturer Based in Liao Cheng Shandong China. Sdarockbolt supply reliable steel pipes for global ground engineering projects. With controlled production, stable materials, and export-ready quality standards, we support contractors and distributors with consistent performance and long-term reliability.Our Key Advantages include:

-

Stable quality for engineering projects

-

Competitive factory-direct pricing

-

Strong production capacity

-

Fast delivery and export experience

-

Technical support from system-level perspective

Grouting Pipe Applications

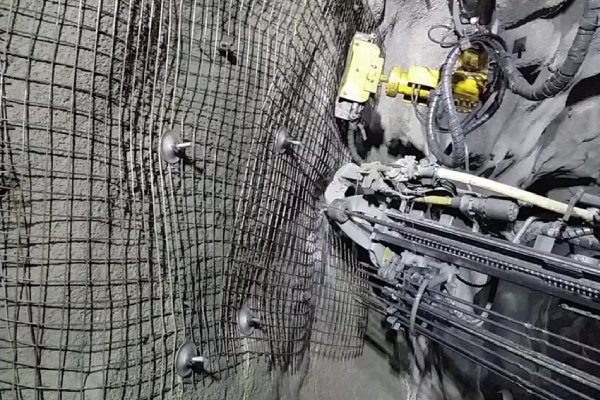

Grouting Pipe are widely used in: Tunnel and underground excavation support, Slope stabilization and landslide prevention, Mining and rock reinforcement, Foundation and underpinning works,Rock bolting in difficult geological conditions

Soil Nailing

Tunnel and Metro Support

Slope Stabilization in Highways

Buildings Foundation Reinforcement